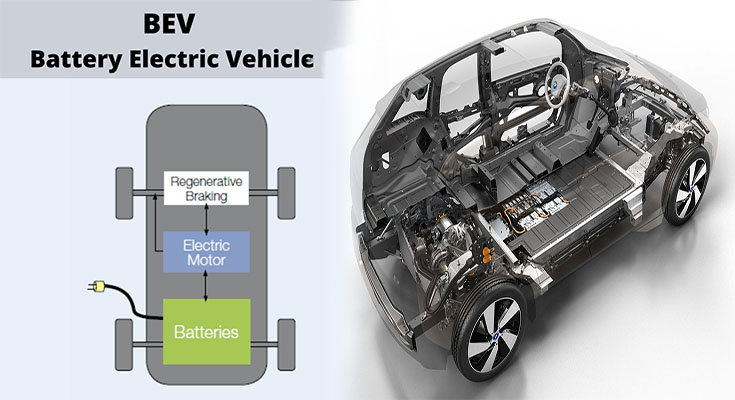

The underlying technology that powers battery electric vehicles is a large pack of batteries, typically made up of around 2,000 lithium-ion cells. These cells are a lot closer to the ones in your cell phone or laptop than their heavier lead-acid cousins, but much more reliable and with far longer life spans.

Technology Advancements

Battery Electric Vehicle (BEV) technology has come a long way since its beginning. In the past decade, there have been significant advancements in energy density, charging infrastructure, EoL, cost-effectiveness, and safety.

A number of companies are investing in solid-state battery technology to advance energy storage. This new technology uses a liquid electrolyte in a solid form, which offers more energy density, faster charging, and lower fire risk.

However, it is still a long way off from production. Analysts predict that solid-state batteries may be a decade away from becoming a mainstream EV battery.

One of the biggest challenges for a new battery chemistry is regulating its temperature. Researchers have developed a thermal modulation system that will keep the battery at just the right temperature without the need for bulky heating or cooling systems. This could make the batteries up to ten times more efficient and increase their lifespan.

Battery Life

Electric cars offer several benefits over conventional gasoline-powered vehicles, including quiet and emissions-free operation and instant torque on demand.

However, like any vehicle, they can have their limitations.

One of the biggest problems is battery life. While gas-only cars can have their batteries replaced once or twice, the battery in an EV is a large and expensive part that needs to be managed over time.

Batteries are typically measured in kilowatt-hours (kWh), denoting how much energy they can store over a particular time period. This is because they need to go through a number of cycles that discharge and then charge when driving.

The EV industry has made great strides in making batteries last longer by reducing the number of cycles they go through, allowing them to provide many thousands of miles before needing to be recharged. This is mainly achieved through ‘buffered’ batteries, which limit the amount of power they can deliver to drivers, along with clever cooling systems and other techniques.

Charging Infrastructure

Charging infrastructure is the system that transfers electric energy from a power grid to an EV’s battery. The charging system can be fast (up to 22 kW) or slow (up to 6.6 kW).

As more and more EVs are sold, there’s an increasing need for chargers in public places. This includes areas where EVs are sold, such as college campuses and retail parking lots.

Moreover, a strong charging infrastructure can help reduce the time for which an EV’s batteries need to be charged. For instance, with fast charging, drivers can charge their EVs in 20 minutes or less.

To make EVs more appealing, states should prioritize equitable access to chargers and make public-charging costs affordable for all people. They could do so through various means, including subsidizing the installation of chargers in less profitable locations, or helping defray demand charges.

Performance

Battery electric vehicles (BEVs) are a growing market, with the goal of reducing emissions and providing a safer alternative to conventional vehicles. They are also quieter and cheaper to operate than ICE cars.

BEVs use lithium-ion batteries, which have high specific energy and high power-to- weight ratios. However, these batteries can also become overheated and can catch fire.

To avoid this, manufacturers incorporate protective measures like thermal management systems and charging restrictions to ensure that EV batteries remain healthy for years to come.

Degradation rates differ by vehicle model and external conditions, such as climate and charging type. Overall, EV battery degradation is minimal.

Battery companies and automakers are working to make these EVs even better by developing cheaper, denser, lighter, more durable batteries. Some give existing chemistries a new twist for incremental improvements, while others are making radical changes to battery form factors or assembly to provide big gains in performance or cost.