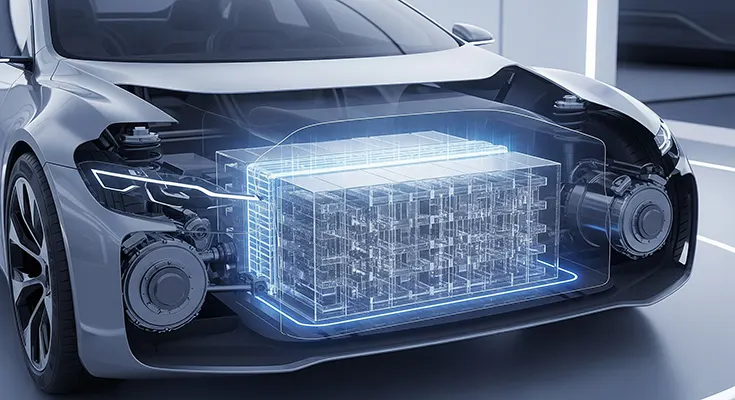

The electric vehicle (EV) revolution is in full swing, but the technology at its core—the lithium-ion battery—still faces significant challenges in terms of range, charging time, and safety. However, a new contender is on the horizon, promising to be the next major leap in energy storage: solid-state battery (SSB) technology. By replacing the flammable liquid electrolytes of today’s batteries with solid materials, SSBs are poised to be a game-changer, fundamentally reshaping the future of electric mobility.

What are Solid-State Batteries and Why are They a Game-Changer?

In a conventional lithium-ion battery, a liquid electrolyte acts as the medium for lithium ions to travel between the anode and cathode. In a solid-state battery, this liquid is replaced by a solid material, such as a ceramic, polymer, or sulfide. This seemingly simple change unlocks a cascade of transformative benefits:

- Higher Energy Density: A solid electrolyte allows for the use of a lithium-metal anode, which has a much higher energy capacity than the graphite anodes used in today’s batteries. This means a solid-state battery can store significantly more energy in the same volume and weight, leading to a massive increase in vehicle range. Companies are targeting a range of up to 1,000 km (over 600 miles) on a single charge, a figure that would effectively eliminate range anxiety.

- Ultra-Fast Charging: The solid electrolyte can handle a much higher current without the risk of dendrite formation (the growth of lithium crystals that can short-circuit a battery). This enables ultra-fast charging times, with an 80% charge potentially taking as little as 10-15 minutes, rivaling the time it takes to refuel a gasoline car.

- Enhanced Safety: The most crucial advantage of SSBs is their inherent safety. The flammable liquid electrolyte in traditional lithium-ion batteries is a primary cause of thermal runaway and fires. By using a solid, non-flammable material, SSBs drastically reduce this risk, making EVs safer and more reliable.

- Longer Lifespan: With a more stable internal structure and reduced degradation, solid-state batteries are projected to have a significantly longer cycle life than their liquid-based counterparts, potentially doubling or tripling their usable life. This would lower the total cost of ownership and reduce the environmental impact of battery disposal.

- Lighter and More Compact: The higher energy density allows for smaller and lighter battery packs for the same range, freeing up interior space in the vehicle and improving overall energy efficiency.

The Global Race to Commercialization

The promise of solid-state technology has ignited a fierce race among global industry giants. Automakers and battery manufacturers are investing billions of dollars to overcome the remaining hurdles and be the first to market with a commercially viable product.

- Timeline: The consensus among industry analysts is that solid-state batteries will begin to appear in premium and luxury EVs between 2027 and 2030. Mass-market adoption is expected to follow in the years after 2030 as production scales and costs fall.

- Key Players: The competition is global, with major players including:

- Toyota: A long-time leader in the field, Toyota is targeting commercialization by 2027-2028 and has partnered with energy giant Idemitsu Kosan to build a key raw material plant.

- QuantumScape: A U.S.-based startup partnered with Volkswagen, QuantumScape is a pioneer in developing lithium-metal solid-state batteries.

- Samsung SDI and LG Energy Solution: South Korean giants Samsung SDI and LG Energy Solution have aggressive timelines, with Samsung SDI aiming for mass production by 2027.

- Solid Power: Another U.S. company collaborating with BMW and Ford to develop its sulfide-based solid-state battery technology.

- Chinese Manufacturers: Companies like CATL, BYD, and WeLion are also making significant strides, with some already implementing “semi-solid-state” batteries in production vehicles.

Remaining Hurdles to Mass Adoption

While the potential of solid-state batteries is undeniable, several challenges must be addressed before they become the industry standard:

- Manufacturing and Cost: The current manufacturing processes for SSBs are complex and expensive. Scaling up from laboratory prototypes to gigafactories capable of mass production is a monumental task that requires new equipment and techniques.

- Material Science: Researchers are still perfecting the materials for the solid electrolyte to ensure high ionic conductivity and a stable interface with the electrodes.

- Durability: The mechanical stress of repeated charging and discharging can cause the solid electrolyte to expand and contract, potentially compromising the battery’s longevity.

Solid-state battery technology is not just an incremental improvement; it is a fundamental shift that has the potential to redefine what an electric vehicle is capable of. While today’s lithium-ion batteries have laid the groundwork for the EV revolution, solid-state technology promises to be the key that unlocks the next phase of mass adoption. By delivering on its promises of greater range, faster charging, and enhanced safety, solid-state batteries will not only make EVs more practical and appealing but will also accelerate the global transition to a sustainable and electrified future. The next decade will undoubtedly be defined by the race to put this revolutionary technology on the road.